Field to Foundry

Circular carbon for the near-zero industrial future

creating sustainable INDUSTRIES THROUGH THE CIRCULAR ECONOMY

steel builds our world

From the buildings we live in, to the transport infrastructure we depend on to get around, to the cutlery we use to eat, to wind farm blades that power our clean energy future, to surgical instruments that save lives, steel is integral to our society.

but it has some dirty secrets

Climate Impacts

The iron and steel industry is responsible for around 7% of global greenhouse emissions and 11% of global CO2 emissions.*

Environmental Impacts

As well as emissions and energy consumption, traditional steel making results in substantial toxic waste water and slag heap wastes with serious environmental impacts.

Health Impacts

Traditional coal fired steel making creates airborne particulate waste products include toxic metals such as chromium, lead and mercury with significant human health impacts for surrounding communities.

*Steel Climate Impact - An International Benchmarking of Energy and CO2 Intensities

NEAR ZERO STEEL FUTURES ARE ON THE HORIZON

Large scale wind and other high energy output renewables technologies have the potential to fuel a clean steel revolution.

CLEANER AND LOWER EMISSIONS STEEL TECHNOLOGIES ARE DEVELOPING FAST

Circular economy solutions like increased scrap steel use, converting waste steel into new steel

Direct reduced iron powered by green hydrogen, cutting out fossil fuels and greenhouse emissions

Adding lower amounts of highly pure carbon post-reduction, allowing more control over the carbon composition of steel and less carbon emission waste

BUT HOW DO YOU REPLACE COKING COAL IN A COST EFFECTIVE MANNER?

Carbon capture from industrial processes is energetically expensive, requires huge capital infrastructure costs, and is a complex and intensive process with a low ROI.

Coking coal is cheap and for now, readily available, but what is the social, environmental and sunk long term economic cost of a steadily rising global temperatures caused by fossil fuel emissions?

The 2021 National Food Waste Strategy Feasibility Study estimated that Australia wasted 7.6 million tonnes of food in 2018-19, equivalent to 152 Sydney Harbour Bridges.

According to their 2023 Sustainability Report, Graincorp alone produced an estimated 4,440 tonnes of waste to landfill, most of which was Dust and Damaged Grain (DDG) and chaff.

MEANWHILE, AUSTRALIA IS IN A FOOD AND POSTHARVEST WASTE CRISIS

THE Solution: MELANITIC FUNGI - SOIL ECOSYSTEM SUPERHEROES

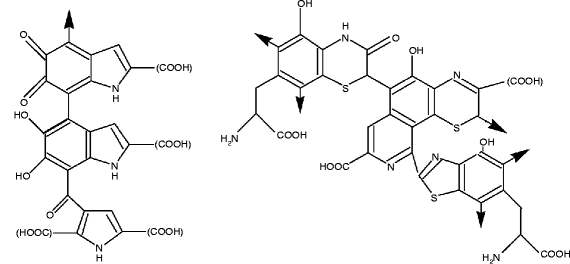

Dark septate or melanitic fungi are a functional class of fungi found all over the world in most ecosystems, one of the most common microbes from the sea to the soil, studied by fungal biologists in private industry and academia globally for their highly unique ecological and biochemical properties including using radiation to directly produce energy and a demonstrated role in carbon storage in soils.

When provided with minimal nutrients and in the right conditions, many of these high carbon producing fungi can convert almost any high carbon organic waste product into concentrated polymerised phenolic carbon.

AND THEY CAN EAT ALMOST ANY ORGANIC WASTE PRODUCT

FIELD TO FOUNDRY IS USING A CIRCULAR ECONOMY INFORMED APPROACH TO TACKLE BOTH PROBLEMS TOGETHER

In Permaculture, problems often create unique solutions to other problems. Wastes can become important inputs to valuable products with the right kind of thoughtful lateral thinking and positive solution focus.

Our customised technology using an organism you can find almost anywhere offers an elegantly simple solution to two curly problems.

WE’VE DEVELOPED AN UNIQUE LOW ENERGY PRECISION FERMENTATION METHOD TO CONVERT ORGANIC WASTES INCLUDING DDG INTO HIGH QUALITY AROMATIC CARBON FOR INDUSTRIAL FEEDSTOCK USE

STRENGTHS OF OUR TECHNOLOGY COMPARED TO OTHER AROMATIC CARBON FEEDSTOCKS

An affordable and straightforward way to make very high quality aromatic carbon for chemical and industrial use, compared to complex graphite mining and refining and carbon recapture processes.

Our unique biotechnology process requires no heat, and very low energy to run, with a very minimal energy demand and emissions output contrasted with greenhouse unfriendly biochars, mined or carbon capture inputs.

The polymeric aromatic carbon produced by our process has far fewer impurities and is more readily usable in an industrial setting than other biomass based carbon options.

Potential INDUSTRIAL market applications

Powdered melanin for use in biomedical, pharmaceutical, and cosmetic industries

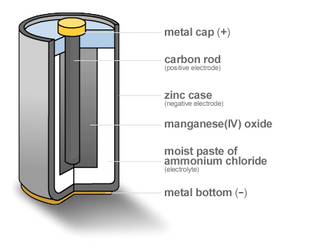

As a zinc carbon or other carbon battery manufacturing input

Replacing coking coal as a carbon source in steel production

As a refractory, a lining used for high-temperature environments like furnaces

Acting as a lower energy and emissions biochar alternative

In the production of high temperature and current electrodes

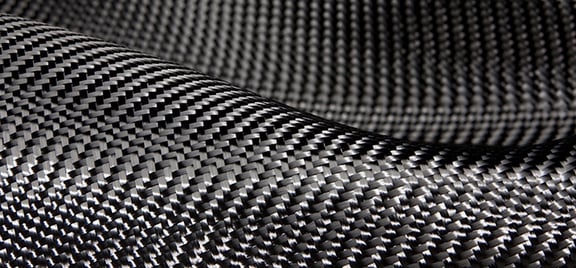

As an ingredient in advanced carbon fibre composite materials

Melanins have radiochemical features which may be suitable for radiation storage applications

According to the European Carbon and Graphite Association’s market analysis the global carbon composite market is expected to grow from 136,000 tons in 2023 to 219, 759 tons by 2028, a CAGR of 10-11%. The global graphite electrode market was valued around 4 billion USD in 2021 with a projected CAGR of 4.6 percent expected until 2029. Fortune Business Insights value the overall global graphite market at 7.28 billion USD in 2023 and project a CAGR of 6.9%. This only represents a portion of the potential market.

BrOADER CHEMICAL market applications

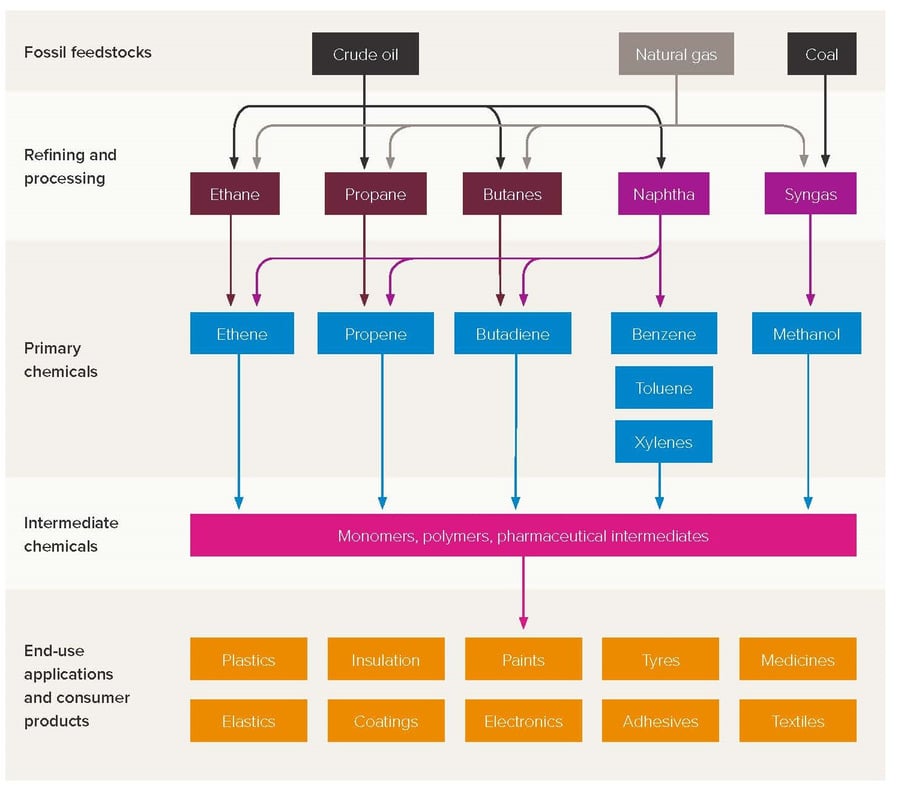

The Royal Society recently released a detailed technical report exploring the drivers behind their push to defossilise our chemical and industrial feedstocks as urgently as possible.

According to the report's lead author Professor Graham Hutchings, Regius Professor of Chemistry at Cardiff University

“Most manufactured chemicals – up to 100,000 of them, according to some estimates – come from just three main sources: oil, natural gas and coal. In other words, the chemical industry – like the rest of society – is addicted to fossil fuels.”

Field to Foundry has a pragmatic, scalable and emissions negative nature based solution to replace fossil fuel chemical feedstocks with sustainable circular economy alternatives.

Table sourced from Catalysing Change: Defossilising the chemical industry - May 2024 policy briefing from The Royal Society https://royalsociety.org/news-resources/projects/defossilising-chemicals/

POTENTIAL AGRICULTURAL AND ENVIRONMENTAL applications

Fungal derived melanins converted from food waste have diverse potential agricultural and environmental applications including promoting plant heat stress resistance*, enhancing soil carbon stabilisation** absorption of heavy metals and a suggested role in reducing the impacts of nuclear pollution.*** Non-living fungal melanins have the potential advantage of avoiding disturbance of naturally evolved biological carbon and nitrogen cycles in diverse soil ecosystems compared to introduced living fungal symbionts, many of which have in practice been found to have negative consequences for these sensitive ecosystems and their greenhouse gas dynamics.****

Engaging in collaborative investigation with agricultural and ecology research institutes and high scale producers of agricultural amendments from a laboratory to field trial scale is a big longer term priority for my market development strategy.

*Rodriguez et al 2008, Stress tolerance in plants via habitat-adapted symbiosis, Nature, The ISME Journal 2, 404–416 .

** Mukasa Mugerwa and McGee 2016, Potential effect of melanised endophytic fungi on levels of organic carbon within an Alfisol, Soil Research, 55(3) 245-252.

*** Mattoon et al 2021, Fungal melanins and applications in healthcare, bioremediation and industry, J Fungi (Basel) 7(6): 488.

****Hoeksema et al 2020, Ectomycorrhizal Plant-Fungal co-invations as natural experiments for connecting plant and fungal traits to their ecosystem consequences, Frontiers in Forests and Global Change, Volume 3.

Business MODEL

Field to Foundry’s business model will centre on 3 key phases in the launch period, focussed on making the most of carbon and nature market opportunities, getting to market quickly with a Stage 1 rapidly prototyped product, and investing in synthetic biology research and development to perfect high quality Stage 2 carbon products for high value industrial, chemical and agricultural market applications

Reducing grain waste to landfill as a voluntary carbon market credit activity

Creating a Stage 1 crude dry aromatic carbon product for use as an industrial and chemical feedstock

Creating Stage 2 refined aromatic carbon feedstocks with chemical and functional properties specifically tailored to high value chemical, industrial and agricultural market needs

WORK WITH US TO SUPPORT THE TRANSITION TO FOSSIL FUEL FREE NEAR-ZERO INDUSTRIES

We're seeking like-minded climate tech, circular economy, agribusiness, industrial, steel making, chemical industry, advanced manufacturing, research and investment ecosystem partners to collaborate around Field to Foundry's early stage development to help us build healthy foundations and get ready to scale. Reach out if this mission resonates with you too.

Alicia Boyd, Founder, Field to Foundry